Electroless Nickel Plating

Zincate-Free Plating

For years, both electroless nickel plating and direct plating on aluminum castings was complicated long process that often ended in failure. SafeGard CC Plating Catalyst revolutionizes the plating industry by simplifying a process that requires less process tanks and less time.

Electroless Nickel plating is now easier, less costly and more foolproof with SafeGard CC electroless nickel plating catalyst. This zincate-free process system is stable, long lasting, easy to use, takes less time to apply and will reduce coating rejects, which increase the throughput of high quality parts. The electrochemical deposition of the “Plating Catalyst” is not directional and once the process starts, the film will deposit itself into any and all recessed areas or small holes.

SafeGard CC Plating catalyst is long lasting and requires only small product additions to maintain the proper concentration balance. This is due to the fact that the electroless nickel plating catalyst is applied very thin (only 100 – 200 nm). This means you will not have to waste time maintaining and recharging zincate tanks. Furthermore, you won’t need to spend time maintaining zincate inventory and use valuable floor space for storing costly zincate replacement and replenishing chemicals.

Furthermore, the same SafeGard CC-Plating Catalyst is used for Electroless Nickel and other direct plating materials. Use this on aluminum, aluminum castings.

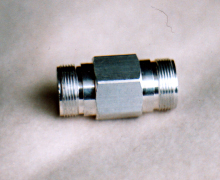

ELECTROLYSIS NICKEL applied over SafeGard CC-Plating Catalyst

6061 Aluminum

6061 Aluminum

Cast 380 Aluminum

Cast 380 Aluminum

Electroless Nickel

Once applied, the organic based electroless nickel “Plating Catalyst” will more or less seal the metal from the outside elements and may, if so desired, be dried and stored in a clean dry area to be processed at a later date by simply soaking the parts in warm (100 – 120 degrees F) mineral free water for about 15 minutes, dipped in 1% aqueous ammonia for about ten seconds and then rinsed again to remove excess ammonia before going into the plating bath. Parts may be processed in a rotating basket if so desired.