Aluminum Deoxidizers & Surface Activators

ALUMINUM DEOXIDIZERS, DESMUTTERS & SURFACE ACTIVATORS AVAILABLE FOR DIRECT PURCHASE

One question that we are often asked is “Should I use an aluminum deoxidizer or not?" High alloy content aluminum alloys will “smut” or leave difficult to remove black-brown deposits when aggressively cleaned. When this happens a “deoxidizer” is used to remove the unwanted inorganic (stains) and to passivate the metal prior to anodizing, plating or conversion coating. Otherwise it is a case by case basis. Aluminum deoxidizers & aluminum desmutters provide excellent paint adhesion and aluminum corrosion resistance. Contact us for further information.

Aluminum Deoxidizing Products

Sanchem 555 - is a three in one product. It works as an aluminum deoxidizer, cleaner and surface activator. This product is typically used for wrought aluminum dip line.

Sanchem 6500F - Aluminum deoxidizer/aluminum desmutter: Our top selling chrome-free liquid deoxidizer for a wide range of alloys. It operates at room temperature and is also an excellent desmutter for aluminum alloys prior to applying chromate or Chrome-free SafeGard CC products.

Sanchem 1000 - This chromate-free aluminum deoxidizer removes anodized coatings and heavy smut that can form when using alkaline cleaners on 2024 or 7075 aluminum. Sanchem 1000 is a nitric acid based deoxidizer contains no fluorides, amines, chromates, iron or heavy metals. It will effectively remove light anodizing when used at 140-150°F, and gives an extremely clear and conductive working surface. Especially useful in removing residue left on surface from a caustic etch.

Benefits of Sanchem 1000 Aluminum Desmutter

There are many benefits to using Sanchem 1000 aluminum deoxidizer over competitive chromate or chromate-free deoxidizers. Sanchem 1000 will save you time by reducing your need for monitoring. Sanchem 1000 is extremely stable having 2-3 times the bath life of competitive products. These features mean that you will not have to monitor the solutions as often as you do with your current deoxidizer or desmutter. This also means that you will have to spend less time adding make-up chemicals. The only products needed to maintain the bath is the Sanchem 1000 powder and nitric acid. Sanchem 1000 does not sludge, so you won't have to drain your tank as often as you would with competitive products.

- Sanchem 1000 removes remove heat scale oxides, anodized films, surface oxides and smut better than competitive deoxidizers in Auger Electron Spectroscopy (AES) and surface conductivity tests.

- Sanchem 1000 removes smut created when using alkaline etches.

- Stable solution does not sludge and has 3x longer bath life than chromate-type.

- Easy to monitor and maintain, only nitric acid and Sanchem 1000 are needed to maintain the bath.

- Sanchem 1000 removes anodized finishes without attacking the aluminum surface below.

- Sanchem 1000 will save you time and money:

- Simple Disposal - contains no chromates, peroxide, fluorides, sulfates, ammonia salts, amines, organics or other environmentally sensitive materials.

- Surface Pitting, very little, if any, even at elevated temperatures.

- Electrical conductivity: Significantly more conductive chromate deoxidizers.

Another benefit of the Sanchem 1000 aluminum deoxidizer is that you will have a cleaner surface to process than competitive products. Tests such as Auger Electron Spectroscopy (AES) analysis and surface conductivity test have shown that the cleanest surface is given when you use Sanchem 1000. Sanchem 1000 chrome-free deoxidizer/surface activator has the ability to remove heat scale oxides, anodized films, surface oxides and smut. Sanchem 1000 not only cleans contaminants from the surface but it also prevents them from redepositing on the aluminum surface.

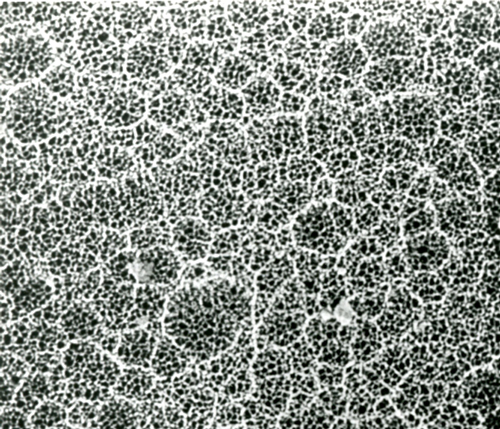

Electron microscope picture of aluminum surface after Sanchem 1000 use

Electron microscope picture of aluminum surface after Sanchem 1000 use

Boeing tests show that Sanchem 1000 removes anodized finishes better than any other product removing the oxide without harming the aluminum surface below. For optimum results when removing anodized finishes, the tank should run between 125-140°F. The removal rate will be much higher at 140°F than at 125°F

The ability of Sanchem 1000 to remove smut so thoroughly gives you an additional benefit of being able to use alkaline etch such as Sanchem 700. Alkaline etches such, as Sanchem 700 are simple to control, easy to dispose of and etch the surface more uniformly than the acid types. Alkaline etches will completely remove all extra organic contaminants that may have been left on the surface. The big disadvantage is that they create a heavy layer of smut on the aluminum surface. Sanchem CC-1000 easily removes all the smut on the surface leaving a conditioned surface.